INOX ORSINI

Stainless steel precision

with artisanal care

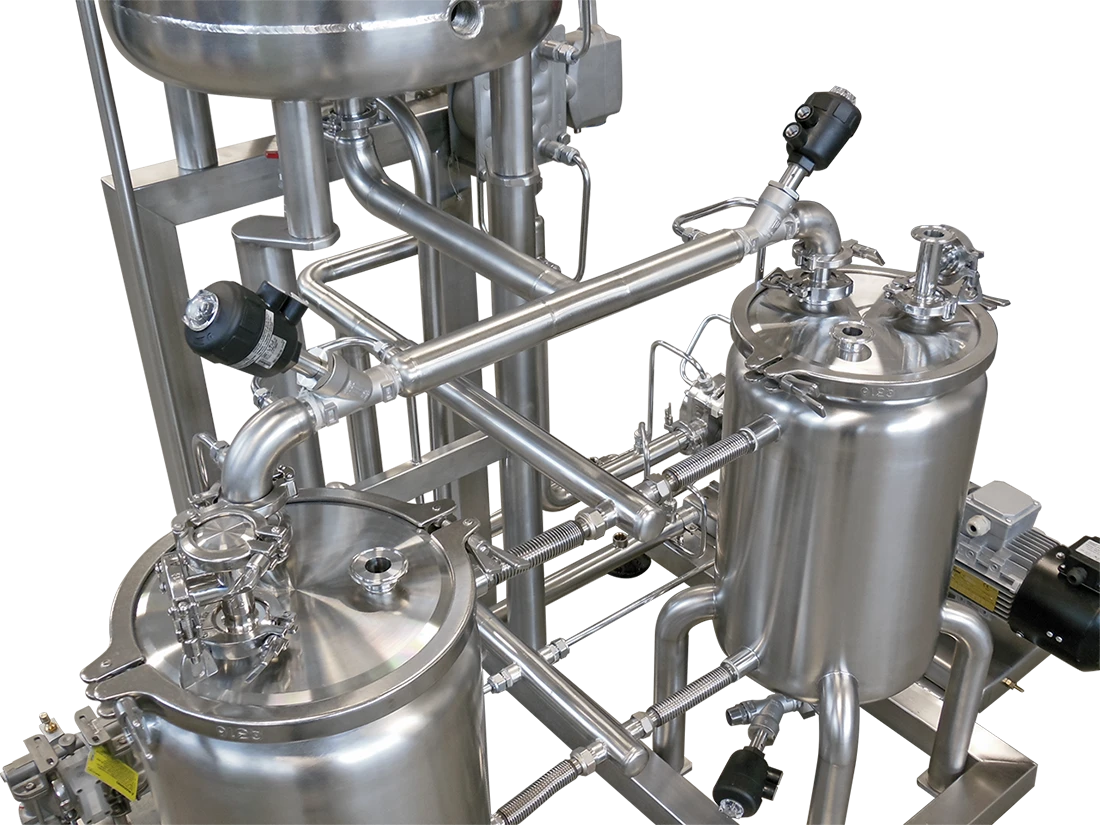

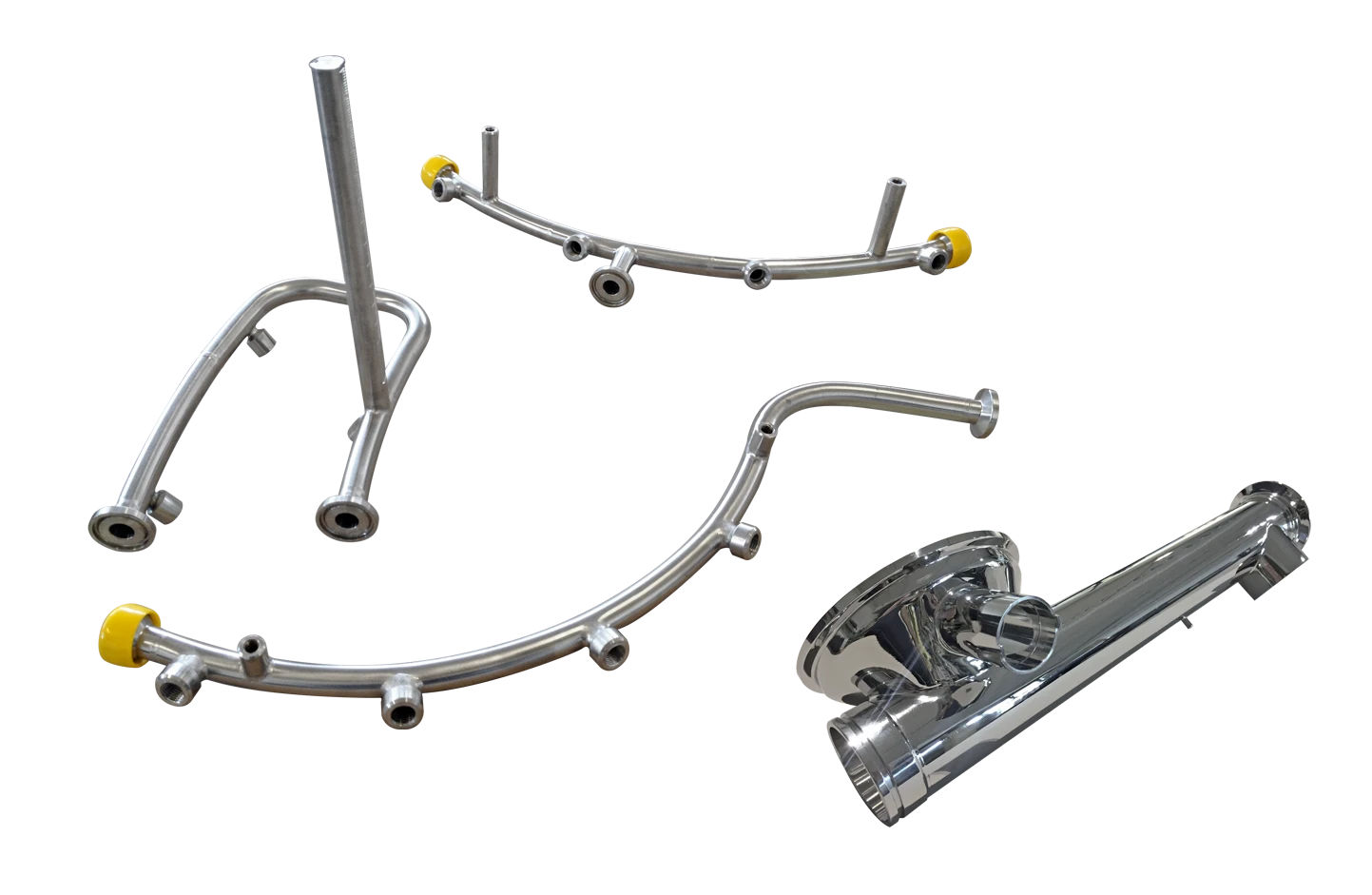

For over 40 years, we have been designing and building stainless steel systems and solutions for the pharmaceutical, cosmetic, and food industries. We are specialized in TIG, orbital, and laser welding, sanitary processing, and custom washing systems, with obsessive attention to quality and material cleanliness.

WE OFFER

- Stainless steel piping systems for sanitary lines, steam, gas, and fire protection

- Certified TIG, laser, and orbital welds

- Custom-made accessories, tanks, and drums

- Gas and liquid manifolds and distributors

- Maintenance and modifications on existing systems

- Washing and cooling skids

Our workshop works exclusively with AISI 304 and 316L stainless steel to ensure maximum hygiene and quality, using components certified to ASME BPE standards.

COMPANY

A tradition of artisanal precision

Inox Orsini was born from a family tradition passed down for over 40 years, combining technical expertise with a passion for outstanding results.

We are a lean and highly specialized company, capable of responding with flexibility, experience and speed to even the most complex demands.

Each project is carried out with care, attention to detail, and superior quality standards—because to us, every weld is a signature. These are our hallmarks:

- Experience, reliability, precision.

- Zero contamination: only stainless steel, only specialized processing

SOLUTIONS

We offer tailored services and solutions for the pharmaceutical, cosmetic, and food industries, including.

WORKSHOP & QUALITY CONTROL

We work exclusively with AISI 304 and 316L stainless steel in a facility designed to meet the highest standards of cleanliness and hygiene. Our equipment includes:

QUALITY CERTIFICATIONS

We can also provide the following quality certifications:

Contact us for a free consultation or to request a personalized quote.

We’ll reply within 24 hours!